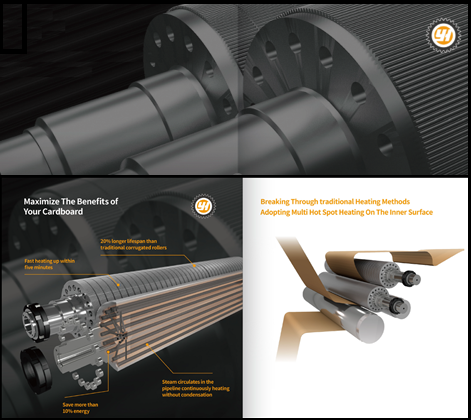

Corrugation Roll is the most important part of Corrugated Cardboard production Line, which abrasion resistance and service life is the main technical index for measuring quality and economic efficiency.

Key Features of High-Quality Corrugation Rolls:

- Abrasion Resistance: The ability of the corrugation roll to withstand wear and tear over prolonged use is crucial. High abrasion resistance ensures consistent performance, reduces the frequency of replacements, and minimizes production interruptions.

- Service Life: The longevity of the roll is a key economic factor. Rolls with a longer service life reduce the total cost of ownership and enhance the profitability of the production line.

- Precision Engineering: The geometric accuracy of the flutes is essential for producing high- quality corrugated board. Any deviation can lead to defects in the final product, such as poor adhesion, uneven flutes, or weak structural integrity.

- Material Quality: The use of premium materials, such as high-grade steel and advanced coatings, ensures durability and performance. Tungsten carbide coatings, for instance, are known for their hardness and resistance to wear.

Advanced Manufacturing Process:

Our Chinese partner, with over 30 years of expertise in manufacturing corrugation rolls, has perfected the production process to meet the highest industry standards. Their state-of-the-art facilities include:

- Automatic Numerical Control (CNC) Precision Grinding Machines: These machines ensure that each corrugation roll is ground to exact specifications, achieving the precise flute profiles required for different types of corrugated board (e.g., A, B, C, E, F flutes).

- JP8000 Supersonic Tungsten Carbide Flame Spraying Equipment: This advanced equipment, sourced from the United States, applies a high-velocity tungsten carbide coating to the rolls. This coating significantly enhances the roll’s abrasion resistance and extends its service life, making it ideal for high-speed, high-volume production environments.

- Quality Control: Rigorous quality control measures are implemented at every stage of production, from material selection to final inspection. This ensures that each roll meets the exacting standards required by the corrugated cardboard industry.

Customization and Technical Support:

Our technical team is highly skilled and experienced in providing tailored solutions to meet the specific needs of our clients.

- Corrugation Roll Replacement.

- Flute Roller Design and Drawing.

- Technical Consultation: Our experts are available to provide technical support and consultation, helping you optimize your corrugated cardboard production process. Whether it’s selecting the right type of roll, improving production efficiency, or troubleshooting issues, we are here to help.